Ballscrew Guys > Anderson America

Ballscrew Guys are specialists in on-site repair and refurbishment of Anderson America Router linear motion systems including ball screw assemblies and linear way guides.

Please contact us to troubleshoot your issue and follow up with a service request with travel and work estimates. See our flat rate specials and inquire about travel splits if your down time is flexible.

Fast response

We come to you to perform all services, typically within two weeks and completed the same day

Low cost

Our refurbishment services are cheaper than buying new or sending out for a regrind

Minimal downtime

We have serviced and installed hundreds of ball screws at manufacturer's facilities

Ballscrew Repair Services

Ballscrew Guys provide low cost, fast-response, on-site ball screw repair and refurbishment services for your Anderson America Routers. Call (877) 768-4064 for immediate consultation.

- Ball Screw Repair and Refurbishment

- Ball Screw Installation and Removal

- Ball Screw End Bearing Replacement

- Linear Way Guide Rail Installation

- Linear Way Guide Block Repair and Refurbishment

- Clean, Flush, and Lube Service

- For mail in service see: Richardson Precision Inc

Gallery

Anderson America

CNC Routers

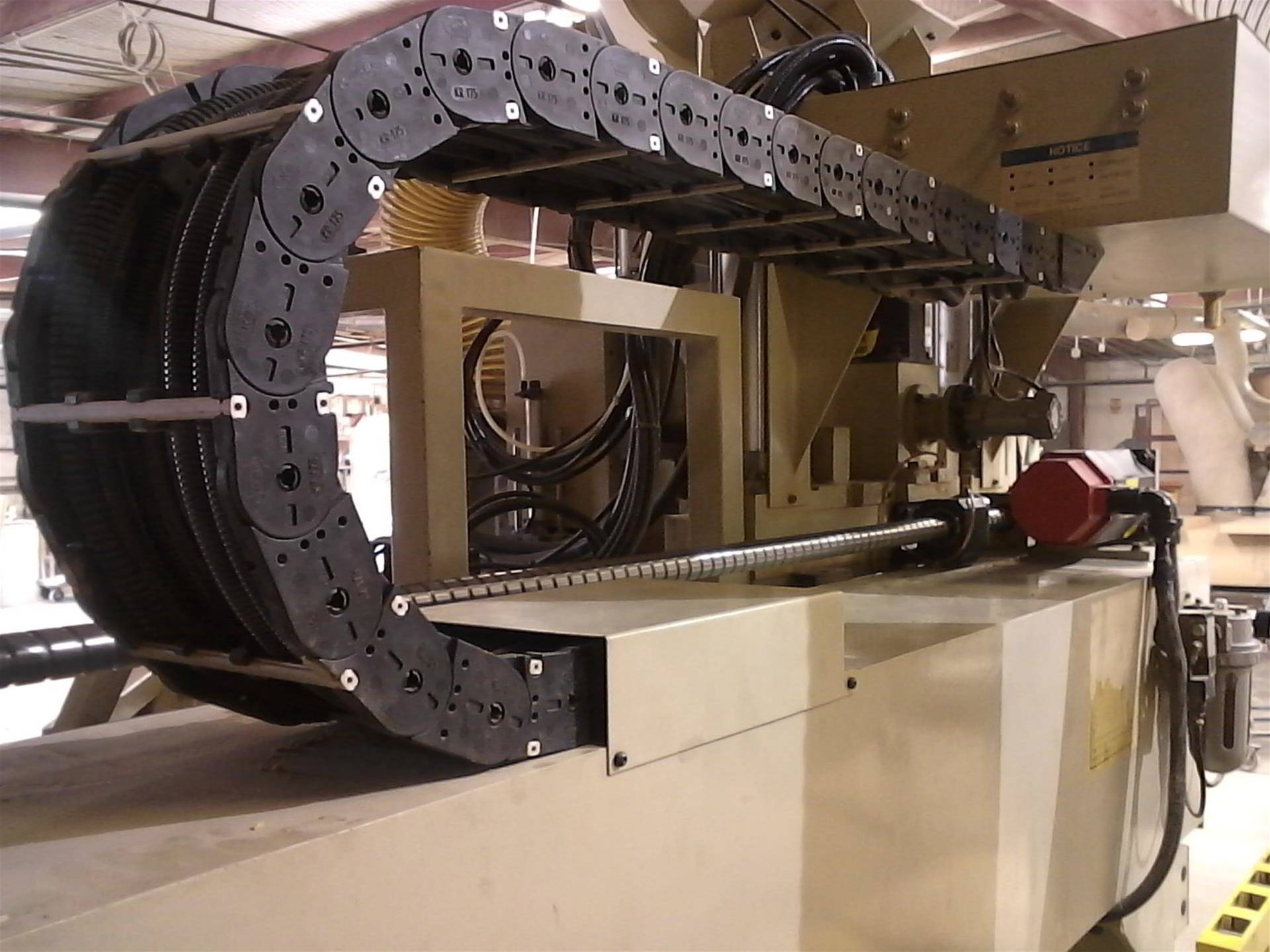

Anderson CNC Router Y-Axis and Cable Bearer

This is the top mounted Y-Axis ball screw for an Anderson Router. This model was without a protective top cover, exposing the entire Y-Axis motion system to debris and sawdust. This, when mixed with grease or oil coating the screw, gets sucked up inside of the the ball nut. Blocking future lubrication and eventually causing the ball bearings inside to stop rolling and circulating.

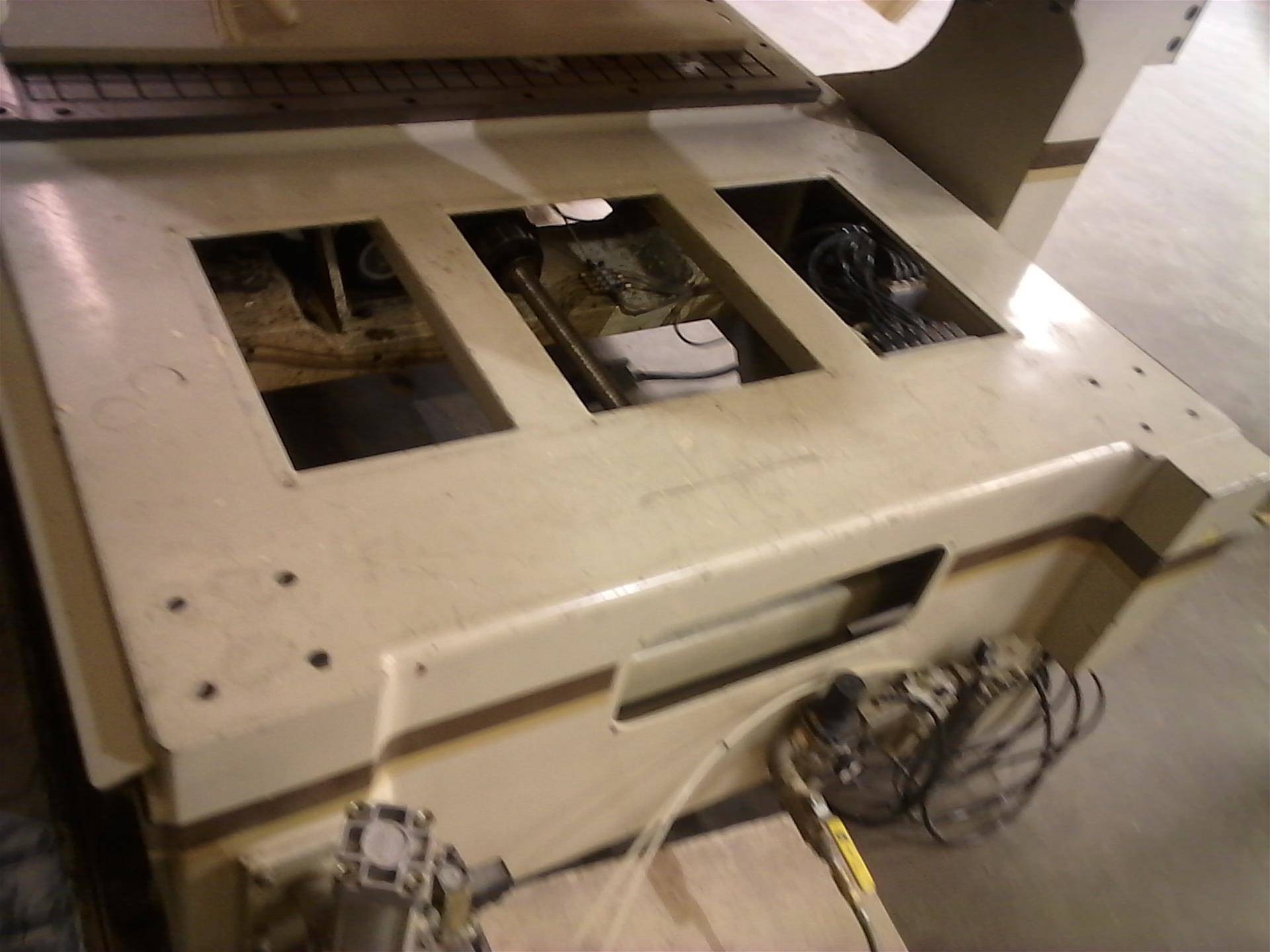

Ball Screw Access Hole

This is the access hole in the machine base where you can access the X-Axis Table Ball Screw. The ball screw needs to be totally removed for refurbishment. Tis is not a simple process.

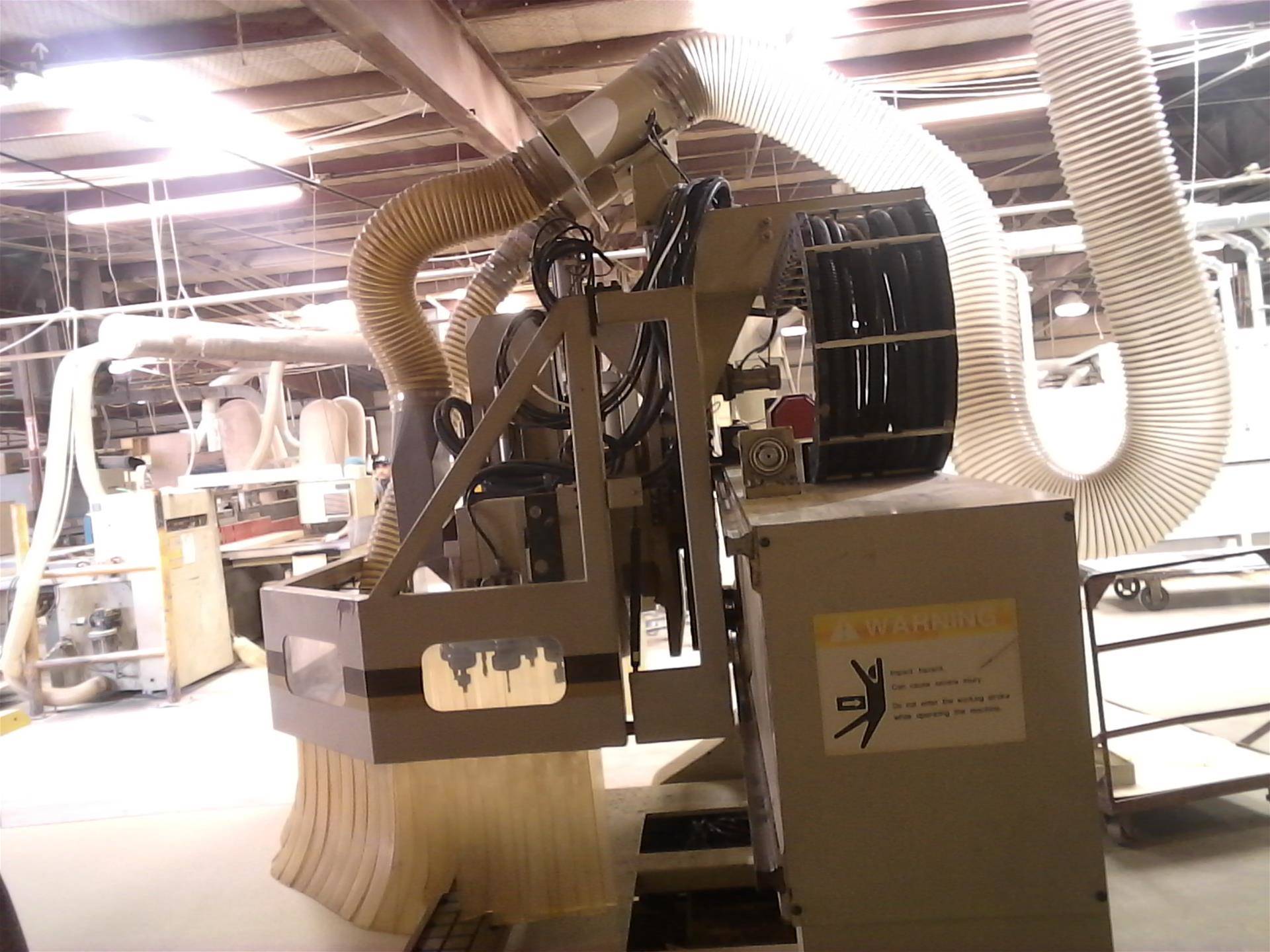

End view of router head

The Anderson Router shown has side mounted Linear Way Guide Rails and Sliders. These often get filled on the top side with sawdust and debris, eventually causing the Y-Axis to no longer slide easily back and forth. It is essential that these components are kept clean, well lubed, yet regularly wiped down.

Access Holes for the other side of the Anderson X-Axis Routers

This is the opposite end of the Anderson Router. Here you can access some of the X-Axis ballscrew parts in addition to service and inspect X-Axis Ball screw lubrication.

Rotation Bearing Housing for X-Axis

This is the X-Axis rotation bearing housing found underneath the table of and Anderson CNC Router. Inside are replaceable roller bearing rings which allow the ball nut to spin around in one location, moving up and down the ball screw shaft. These parts generally are well lubricated and do not often need replacement.

STAR Ball Screw Ball Nut with Belt Driven Rotation Bearing

Here the German STAR Ball Screw assembly is being pulled from the rotation bearing mounted in the Anderson Router X-Axis Table Yoke. There is quite a lot of disassembly to reach this point, with still yet more to come. The screw shaft is multiple windings around one rod. The ball nut itself rides on two tracks. This interior ball nut is often contaminated from sawdust and debris. It's lubrication delivery also being passive through the rotation bearing, so when mixed with crud the critical bearing surfaces are often starved for lube.

Complete STAR Ball Screw Assembly with Rotation Bearing and Table Yoke

The Entire Ball Screw and Nut assembly taken out from underneath an Anderson CNC Router. The entire component was cleaned prior to disassembly.

STAR Ball Nut removed from External Rotation Bearing

Here is the internal STAR Ball Nut removed from the External Rotation Bearing and Anderson X-Axis Table Yoke Housing. These roller bearings typically are common and relatively easy to find. Notice the greasy and dirty oil covering everything. This is all saw dust media mixed in with the lubrication.

Models

Ballscrew Guys provide low cost, fast-response, on-site ball screw repair and refurbishment services for your Anderson America Routers. Call (877) 768-4064 for immediate consultation.

Anderson America

| Type | Series | Models | |

|---|---|---|---|

| Routers | - | Depends on size (Small) Depends on size (Large) Stratos |